iC-LNG: serial/parallel absolute-value device requiring only approx. 8 x 7 mm of board space

The new iC-LNG device is a multichannel, optoelectronic scanner specifically designed for the capture of absolute position date for linear displacement measuring systems or rotary encoders. The chip's extremely small design is achieved by combined scanning of a 10-bit Gray code in addition to an analog signal track which is evaluated using real-time interpolation and which extends the position value to 16 bits.

iC-LNG's sensor array requires a code width of just 5.4 millimeters, enabling smaller code discs or larger hollow shaft diameters to be used. The LED lighting unit is also much more compact; iC-SN85 provides a suitable light source with a particularly energy-efficient LED. iC-LNG controls the level of illumination and acts as a monitor; a separate alarm output indicates any lighting errors.

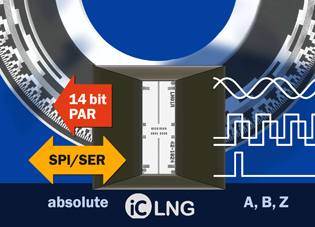

Offset and amplitude compensation has been integrated for the correction of the analog track signals which are also output as differential sine and cosine signals through four ports. The interpolation error can be reduced by signal correction to gain more precise position data. This setting is also beneficial to the incremental signals that are also provided; iC-LNG supplies A/B/Z signals with 1,064 to 16,384 pulses in selectable binary grades.

The position data can be output in parallel (up to 14 bits) or in series using a fast shift register. Clock rates of up to 16 MHz are possible for cycle times of less than one microsecond. Alternatively, the 3.3 V-compatible SPI interface can be used which was implemented for the configuration of the device.

iC-LNG operates between 4 V and 5.5 V within an operating temperature range of -40°C to 110°C. All functions are available up to a maximum speed of 12,000 rpm. The device comes in a 30-pin optoBGA package with a preassembled reticle and requires just approximately 7 mm x 8 mm of board space.

iC-LNG supplements the iC-Haus portfolio of absolute optoencoders with its medium resolution, complexity, and simple operation using the SPI interface. LEDs, code discs, a demo board, and a ready-to-operate microcontroller board which can be connected up to a PC are available for evaluation. |